This investigation was a joint effort by The Examination, The Post and Courier, Columbia Journalism Investigations, and RTBF, and published in collaboration with Mother Jones. The story is part of the Climate Desk collaboration.

The promise of lithium-ion batteries is to power propulsion without reliance on petroleum. With governments worldwide incentivizing their adoption, lithium-ion batteries are seen as crucial to a green transportation revolution. They reduce emissions, promote independence from fossil fuels, and are driving a surge in electric vehicle purchases, expected to make up half of global car sales within the next decade.

However, as battery production scales up to address climate change, a hidden risk emerges that few outside specific areas may be aware of. Companies known for releasing harmful “forever chemicals” linked to cancer and other illnesses are now involved in EV battery development, often with significant taxpayer support. These companies are accused of misleading regulators, withholding information, and contaminating communities while making similar products.

Transitioning from gas-powered vehicles to electric ones is key to reducing harmful emissions and combating climate change. Making lithium-ion batteries in a way that does not harm communities is crucial.

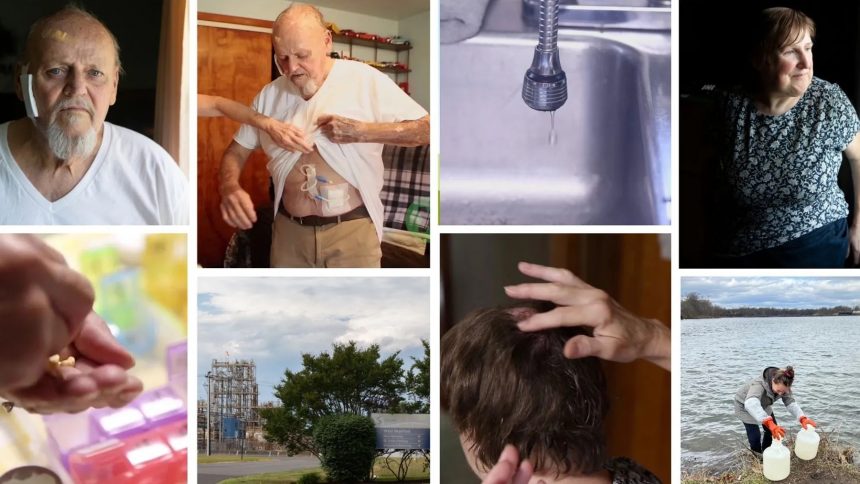

In Pierre-Bénite, France, chemical giant Arkema produces PVDF, a polymer used in EV batteries. Recent protests and legal actions have been sparked by the chemical waste generated at this facility. In Pedricktown, New Jersey, residents like Richard and Kim Bond are fighting a legal battle against chemical companies, including Arkema and Solvay Specialty Polymers, alleging health issues due to forever chemicals.

In Augusta, Georgia, Solvay Specialty Polymers received a hefty grant from the US Department of Energy to expand its facility to exclusively produce PVDF for EV batteries. While the company assures the public of safety measures, experts remain cautious. The industry’s reliance on PFAS, known as forever chemicals, in battery production creates additional concerns.

Chemical companies’ lack of transparency in production and the supply chain is a significant issue. Cases like Chemours contaminating water sources with forever chemicals illustrate the risks associated with manufacturing processes. The need for greater transparency and safer production practices in the battery industry is clear to experts.

In conclusion, the transition to electric vehicles is crucial for reducing emissions and addressing climate change. However, it is equally important to ensure that the production of EV batteries does not harm communities or the environment. Greater transparency, safer production practices, and public awareness are essential in the development of a sustainable and environmentally friendly transportation infrastructure.